Kaizen: 5 continuous improvement areas to explore with your team

Published on February 14, 2025

Kaizen: 5 continuous improvement areas to explore with your team

Do you want to improve your product or service quality or make sure you keep to deadlines or budgets? Do you want to avoid turning your organisation upside down from one day to the next?

Then the Kaizen method is made for you! This process is at the heart of Toyota’s success and enables teams to improve, even without major resources. Here are 5 areas for you to explore to get started.

The whole Kaizen process is based on one ultimate objective: satisfy the customer!

Stock management, production management and quality audits are just a few of the areas where your team needs to search for excellence, to provide your customers with the products and services they expect, on time and at the best price. It is not surpsising then that Totality Quality Control (TQC) is the cornerstone of the Kaizen methodology.

TQC covers a host of aspects. For instance, in industry, it may involve double verification of each part, or the establishment of “quality circuits” or “continuous improvement groups”. These are quite specific processes, but they may provide inspiration to all teams in all sectors.

The first lesson to remember from the major successes which have been achieved using the Kaizen process (with Toyota leading the way) is that it is simple to be customer service-oriented when several people within the company guarantee it. One of the solutions to deliver better products or services may then be to stop entrusting quality audits to a single person, and place this responsibility on a team (pairing, quality circle, etc.).

The term “Kaizen” is a contraction of two Japanese terms: Kai ("change") and Zen (for better). In two words, “continuous improvement“. This means that when you think Kaizen, you align with the idea that excellence needs to be worked at on a daily basis, step by step.

While being the symbol of Toyota’s production system, this approach involves slight improvements, in small steps, unlike the major leaps forward that can be seen in innovation. The benefit? Execution quality is constantly improved, and deadlines and costs are controlled to ensure better stock and production management, without imposing any sudden changes on the men and women who, both individually and collectively, take part in the process.

While the Kaizen method does not require any significant financial investment, it does require major commitment from all employees, from all activities and at all managerial levels.

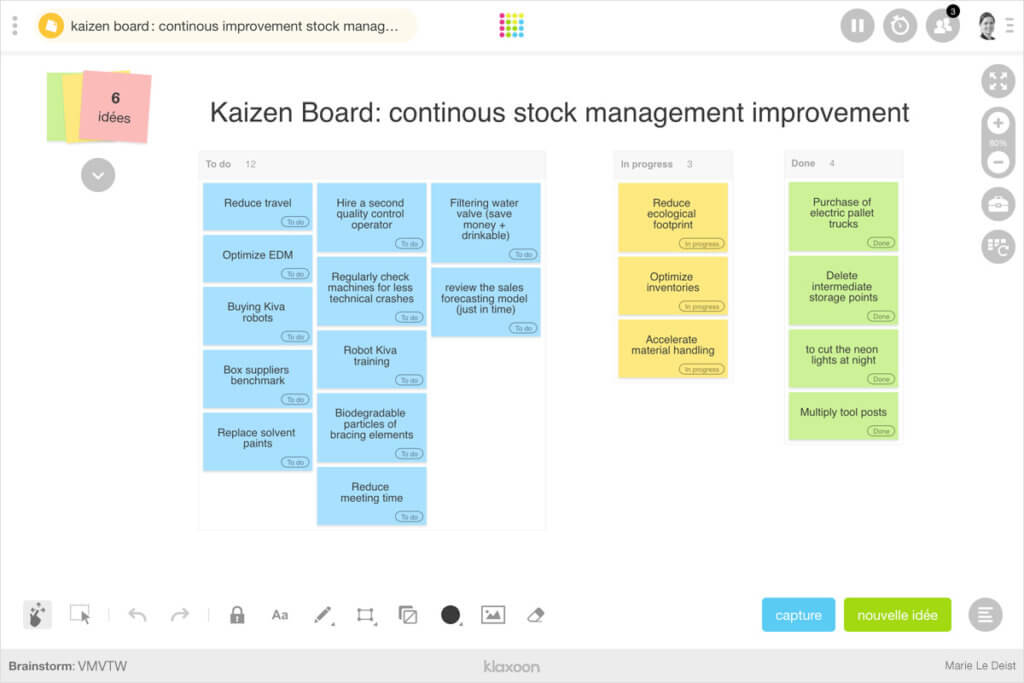

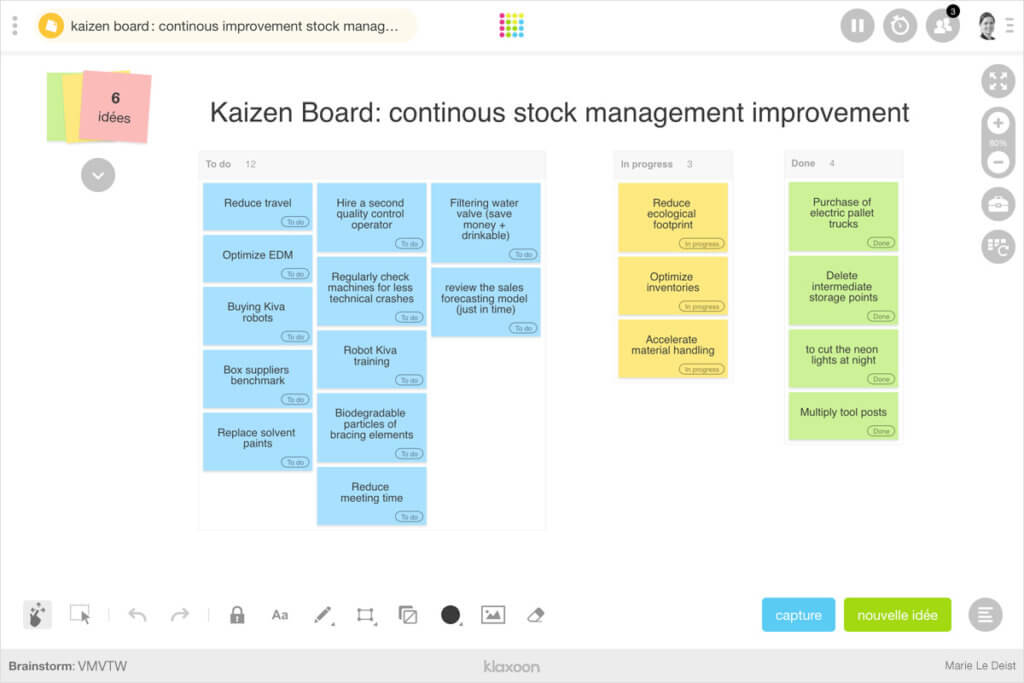

The improvements which are put in place are tiny, but what’s special about them is that they come from everywhere. To be able to increase the quality of execution constantly, the companies using the Kaizen method the best way invite each person to say what they think can be improved, and get the collective to discuss the areas for improvement to be put in place.

As the theorist Masaki Immai says, the Kaizen method is a system where “each person is made responsible to achieve the cult of the best“. The process is therefore perfectly in step with Lean Management, a method which involves improving a company’s performance by developing all of its employees.

When transposed to the scale of any team, the process, which is very well-known in the industrial sector, maintains its full meaning: each person’s opinion counts and through collective discussion, the team can achieve excellence.

To achieve the best quality of execution possible, the easiest thing is still to eliminate sources of difficulty as early as possible in the manufacturing process.

In the Kaizen system, the emphasis is placed on solving problems in advance, with anticipation at the forefront. This method makes perfect sense, and may be rolled out very easily in your day-to-day business, by asking each person to make suggestions even before the problems arise.

If you want to deliver the best product or service at the best price, and as quickly as possible, you have no other option: you have to track down the waste in all its forms!

Taiichi Ohno, the Toyota production system’s founding father, identified 3 main types of waste to be eliminated:

This is an analysis grid to use within your team, for you to find the solutions to eliminate errors, waiting times and more. In short, anything which is unnecessary!

The advantage of the Kaizen system is that it can adapt to any working environment, and be rolled out infinitely. It is implemented on a daily basis, in multiple forms. In concrete terms, it many involve (to list just a few potential actions):

You too can adopt Klaxoon!

Unlock your teamwork potential